Oil additive based on copper oxide (CuO)

Copper Oxide (CuO) is widely used in advanced industries like aerospace and mechanical engineering due to its electrical properties, anti-wear, anti-corrosion, and high thermal stability. This compound is added to oils to improve their performance at high temperatures, enhancing their anti-wear and anti-friction properties. One of the key characteristics of CuO is its high temperature tolerance. It can operate effectively at very high temperatures (above 300 ºC) without chemical degradation.

Therefore, it protects lubricating oils from thermal breakdown. This makes CuO highly beneficial in heavy and advanced industries that deal with high-temperature environments. Also, its good electrical conductivity makes it an ideal choice for applications requiring resistance to electrical currents. For instance, the electrical conductivity of CuO is particularly useful in electric motors and generators. Because lubrication and the ability to withstand electric current are both essential. CuO also possesses catalytic properties that can accelerate the oxidation of organic materials. This makes it suitable for use in high-temperature and high-pressure systems.

Ideal for applications

- Heavy industries and machinery operating under high temperature and pressure conditions.

- Complex equipment such as lathes and thermal devices.

Pin On Disk Wear Test

In the Pin-on-Disk test, the coefficient of friction is examined. For this purpose, two samples were tested according to ASTM G99 standards: a base oil and a base oil mixed with 0.4% Wt CuO additive.

The test was conducted at a temperature of 100 ºC according to ASTM G99 standards. The applied force was 200 Newtons, the sliding distance was 1000 meters, and the motor speed was 250 rpm.

In this test, it was observed that the coefficient of friction for the base oil mixture with 0.4 % Wt by weight of CuO was lower than that of the base oil. This reduction in the coefficient of friction shows that the CuO nanoparticles have helped improve the lubrication properties of the oil.

It appears that due to their small size (on a nanometer scale), CuO nanoparticles can easily penetrate the pores and surface irregularities of the components and fill them. This property helps smooth the contact surfaces and reduce direct contact between metallic surfaces. These nanoparticles can act as a thin, slippery layer between the metallic surfaces in contact and reduce friction. This lubricating property was maintained even at 100 ºC. This shows that these nanoparticles are effective even at high temperatures.

Images of the four-ball test: The test was conducted with an applied force of 392 Newtons, over a time of 3600 seconds, with a motor speed of 1200 rpm.

Wear Test (Four-ball Test)

The four-ball test or wear test is another test that can determine the effect of various additives in oil on the amount of wear. Below are the images of this test to compare the wear level when using base oil and base oil mixed with CuO-based additive.

In the four-ball test, images (a) and (b) represent the base oil without the CuO additive. They show wear track lengths of 1581.73 μm and 1682.29 μm, respectively. Images (c) and (d) correspond to the base oil containing the CuO additive, which wear track lengths of 870.99 μm and 759.30 μm, respectively.

In general, these images show that when using base oil, the surfaces are exposed to direct wear, and the effects of wear are clearly visible. The wear tracks are long and extensive. This shows a greater damaged surface. However, in the presence of the CuO nanoparticle-based oil additive, due to their very small size (on a nanometer scale), they can penetrate the pores and irregularities of the surface of the parts and fill them. This filling results in a smoother contact surface between the two metal parts. They reduce the microscopic contacts between the surfaces and as a result wear is minimized. These nanoparticles also improve heat transfer and prevent an increase in surface temperature.

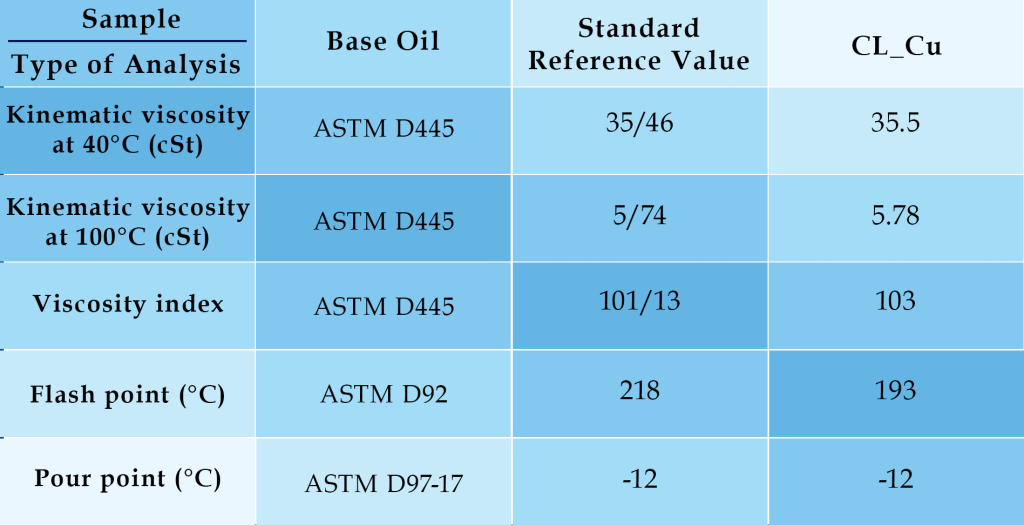

Table: Oil additive based on copper oxide (CuO) nanoparticles